Eelume, a spin-off company from NTNU develops underwater snake robots, which will be used for inspection and maintenance of subsea fields.

The robots must be permanently stationed underwater in the field and can carry both autonomous and remote inspections. Thus, they do not surface vessels with crews both cost money and limit their use.

In addition, snake shape that robots are going on far more seats than the current square ROVs.

The robots will thus act as a kind of self-custodian on the seabed .

Self-robotic

Eelume works with both Kongsberg Maritime and Statoil, to complete the development and qualify the technology.

Kongsberg will contribute their 25 years of experience in marine robotics, while Statoil provides access to offshore testing robot.

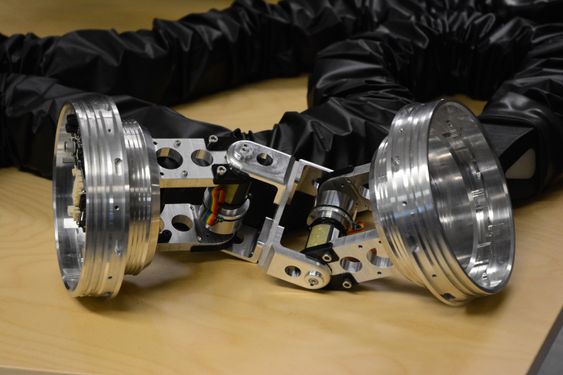

The snake robot will be based on the modules connected with multiple joints, which allows it to move like a snake in the water. In addition, the thrusters. The size can also be customized according to different needs.

It will be used for inspection and basic maintenance tasks, such as cleaning and operation of valves, tasks that make up a large part of today’s inspection and maintenance operations.

It will be equipped with sensors for navigation and camera, as well as the necessary tools, such as grapples.

– robots will be long and slender, with a cross section of 180 millimeters. This makes them flexible, and they will have a unique opportunity for the access on subsea installations. There are many places where today’s difficult for ROVs to get to because of the size, they are big boxes with robotic arms. Our technology is a self-propelled robotic arm, we have removed the body completely, says Paul Liljebäck, CTO of Eelume, to TU.

stationed on the

at the robots are permanently stationed at the fields means they can be mobilized when needed, without surface vessel required to launch and manage them.

the system can perform own autonomous operations and it is possible to remotely control operations from land.

– How will it be possible with much more continuous inspection. Instead of once every six months, the robots go out every day. It gives new opportunities to monitor changes at the installation. It will make it much safer, says Kristin Y. Pettersen, CEO of Eelume.

The robots are designed for high durability under water, and will initially be powered by a cable to the actual installation. Eventually the plan is to go over to the batteries to be charged in separate charging stations under water.

Have great faith in technology

Currently consists technology of a prototype in pieces on the table at NTNU in Trondheim Amos. The design is clear and we are working with the actual machining. According Liljebäck there is no greater shear in the sea before the technology is completely ready. The biggest challenge is about adapting it to different infrastructure on the seabed.

This autumn, it will be ready to be tested in Trondheim Fjord, but it is not yet determined how or when the technology is taken to an offshore field.

Statoil is still ready to help with subsea installations if the final system delivers what it promises – potentially revolutionize the maintenance of subsea fields.

Technology Officer Elisabeth Birkeland Kvalheim says to TU that the company strongly believe snake robots.

– We believe that using robotics as this. To avoid having to withdraw a vessel with crew, to launch an ROV, will be a very development. It’s hard to say exactly how much this technology can save us, but you can the be based on day rates for such vessels and only Statoil alone has 500 subsea wells, she points out.

Kvalheim notes that Statoil has faith to help small technology companies with testing and qualification of technology.

– It is often here that we find the most different and radical ideas, she emphasizes.

– Radical technology

bear Jalving in Kongsberg Maritime’s subsea division explains that they take with them their 25 years of experience in underwater technology into the project.

– When we developed Hugin AUV 90s it was through a similar collaborative project like this. Now we repeat the story in a completely new collaboration, where everyone contributes their strengths. And it is important, for this is not simple technology, he says, to TU.

He notes that the company contributes its expertise, in addition to some more specific components of the technology. Including some software required for the robot to be permanently installed on the seabed, as autonomy, navigation, communications and remote control.

– We think this will be a contribution to make the oil industry more cost effective. This radical new vehicle technology, coupled with that there is a resident capacity, could provide substantial savings because it introduces new ways of doing routine work. In addition, the operator avoid downtime by immediately able to scramble and solve problems when necessary, he emphasizes.

No comments:

Post a Comment